Dear people! Good news: MaschinenBoom was extended to happen until the end of 2021! More time to explore our Hangprinter!

Together with the museum we started to think what we could test out with Hangprinter. We wanted to print more complex parts than huge vases only (which show what's possible in size for best, so far). We have large volume capacity and big layer size. Ideal to do something huge and strong. We came up with the idea of making a soap car in the style of the fourties, assembled from mostly printed parts (and some required standard parts like ball bearings, rods, screws, ...). I began modeling some parts and printing them.

Since reopening the exhibition i spent 5 days in total of printing with Trikarus and dived a bit deeper into print settings to do our experiment. Some problems i had to fight with in that time:

- effector is lifting from the bed and E3D Aero extruder is slipping (mounted a new PLA filament spool with mass of 5kg). I modded the unwinding process of the filament by adding extra weight (just put some heavy printed example gear to the top). Additionally i needed to find out a well documented setting for the hobbed gear force at the extruder.

- PLA parts with large mass lift up (thermal warping)

- PrusaSlicer parameters still imperfect to guarantee stable print (several printing aborts). I updated the PrusaSlicer profile multiple times (i tried to enabled volumetric extrusion but i had no luck with it yet - having wrong parameters). I repeated some issues from the past and stepped into old mistakes i was thinking i already solved. Finally i slowed down the printing process, adjusted temperatures and some more settings

- first layer adhesion not well. Readjusted some anchors (especially C anchor had to be adjusted in height)

- ...

I added some more videos to our Peertube instance which show some issues:

- https://videos.stadtfabrikanten.org/w/eaBrFKnXJM6fFKqvdr9ryz

- https://videos.stadtfabrikanten.org/w/6YEKEz5x6qaRshsKTrygYX

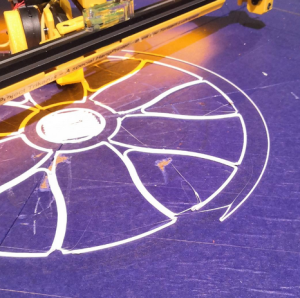

Finally the first result after 5 days is a finished wheel part with large warping effects (nearly 1 cm of vertical error). But it is good enough to test for practical use. It's undestroyable. You cannot bend it. But it does not fit to the tire i bought. So we come back to the roots of rapid prototyping: I have to resize the part and print it again. To fix the issue with warping i ordered some adhesive spray to test out what will happen on the blue tape. I will try it out next time i am at Trikarus. See our calendar.

Comments