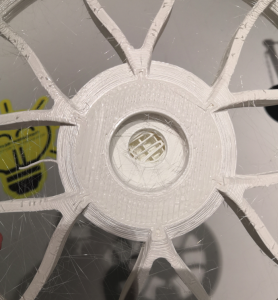

The last two days of public Trikarus shows generated new insights again. At 04.09. i finished the print from august and also started to print a new soap car wheel body with finer layer quality (0.5 mm instead 1mm). I did this because the last wheel body broke again and i think the layer bonding was not good enough (as one factor).

The broken wheel (finished wheel body number 2)

Pumped air divided it into 2 parts - print errors reduce axial stability

Wrong PrusaSlicer version

While generating the GCode i also recognized i used the wrong PrusaSlicer version which removed some options i previously configured (like ironing). That's an issue belonging to Fedora by the way. The Source repo did not contain the recent PrusaSlicer version. Now i am using PrusaSlicer 2.4.0 Beta. This also supports Repetier Server API to upload jobs directly to the server.

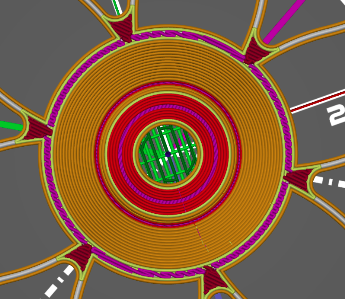

Some layer quality check

Parallel to the messing with PrusaSlicer versions and print parameters, i made some comparison of the virtual and physical structure. I think the print profile gets better and better.

MisfitTech SmartStepper Displays

While maintaining the printer i checked the OLED displays of the MisfitTech Smart Steppers. As i mentioned earlier, the displays seem to age quickly. A complete shutdown/power off did not change the behaviour. So i think the will die in 1 or 2 years completely maybe.

Bonding on glass surface / high amount of thermal energy

The print, started in august (Another round to fight against warping) finished at 04.09. I exspected to have high resistance removing the part from the glass plate. And it was correct. It was ultra hard to get off the part. But the quality was really good. No warping.

Unfortunately, the new print, started at 04.09. and continued at 26.09., lost its good adhesion on the glass plate. I paused the print over 3 weeks. In this time the sticking got worse and the brim got fissures.

I made some experiments with massive parts. The following video shows a cuboid volume which is cooling down. We can form the PLA by hand even 60 seconds after finishing the print. This effect greatly helps to imagine how large interenal stresses are generated in regular print parts.

Line ruptures (finished wheel body number 3)

Yesterday my print from 04.09. got worse after some hours of continued print. The line C2 got defect You can see large shiftings in the printed part. I replaced C1 and C2 line at the sime and needed ~1 hour to do this.

The shifted geometry of the part

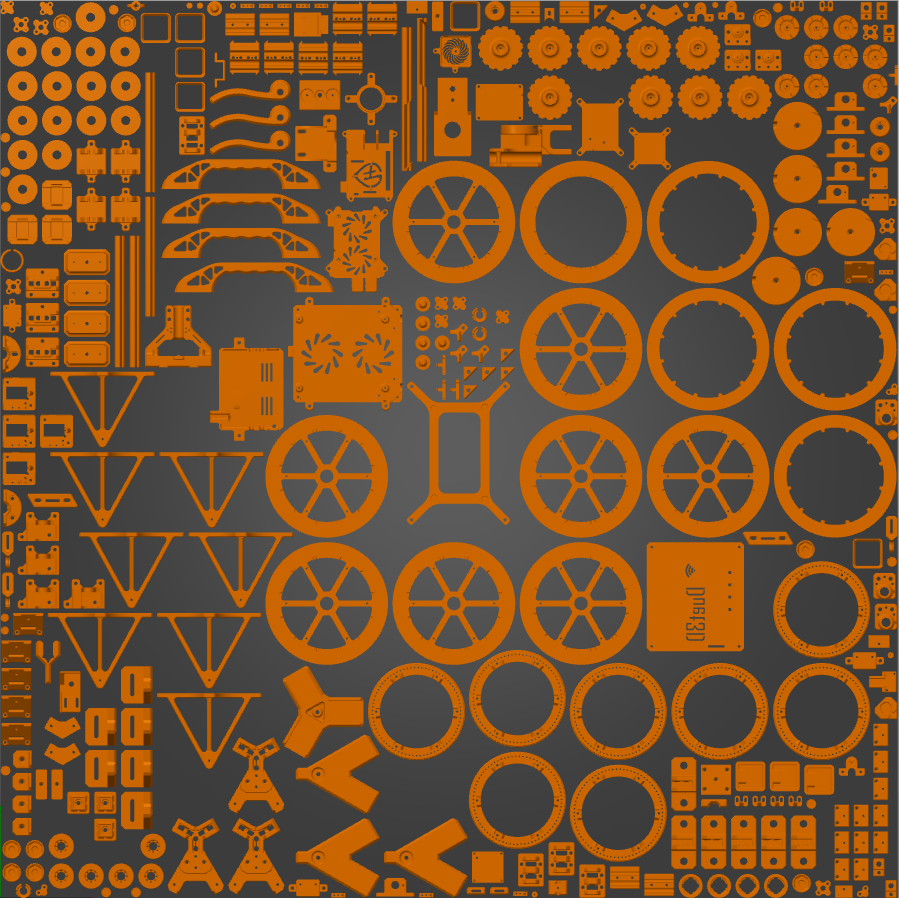

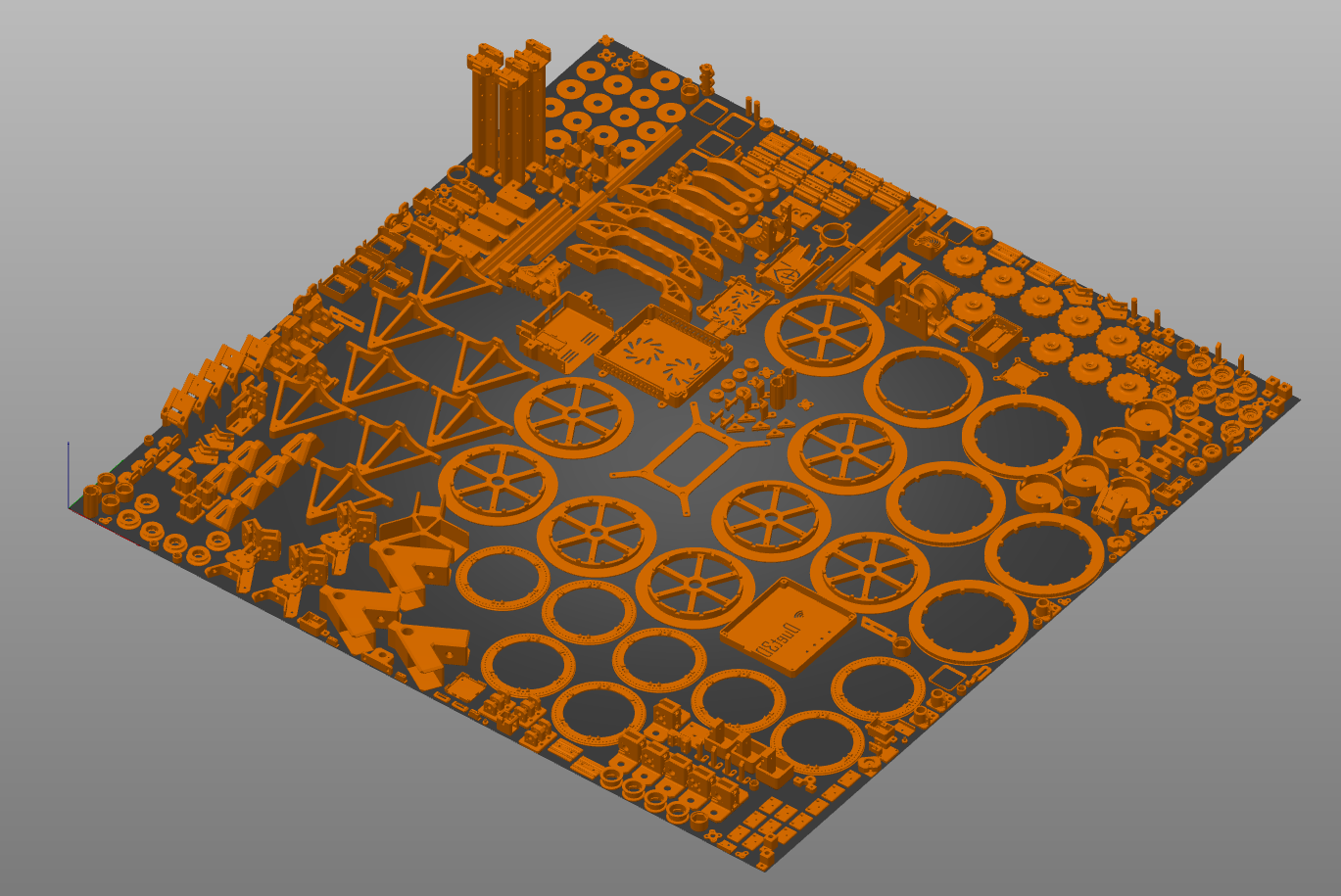

A review of Trikarus' print parts

By the way i tried to count all the printed parts of Trikarus. I came up to 339 parts. Have a look:

Comments