At 19. and 20. june i was able to start printing and testing with Trikarus again. I did a lot of experiments to update the PrusaSlicer parameters. I uploaded recent settings to our gitea versioning server. Some experiments and adjustments i did:

Ironing

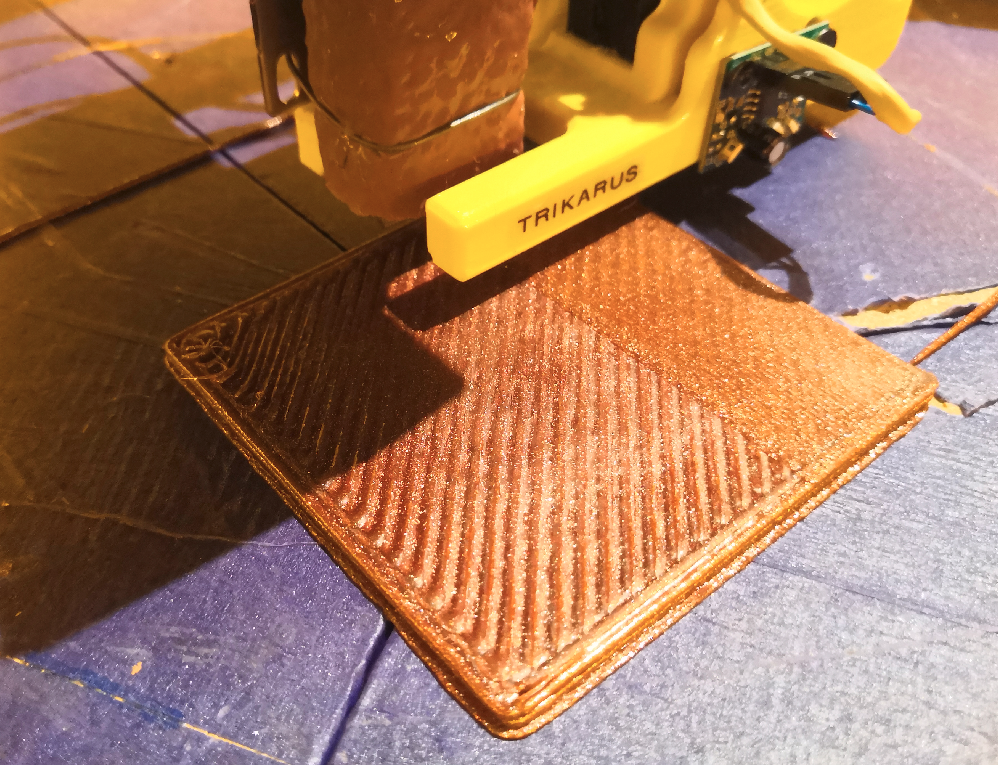

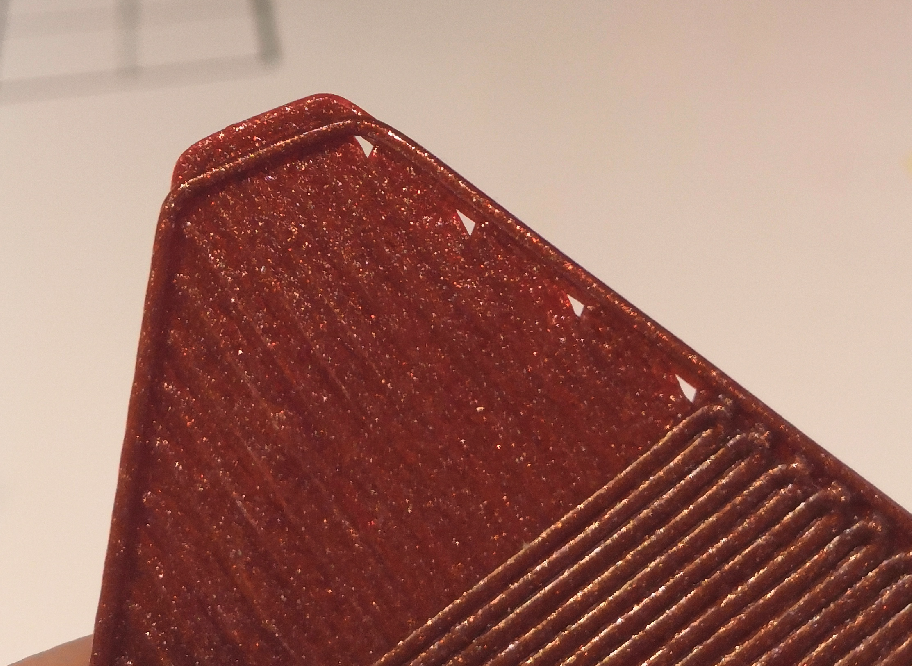

Ironing is like flattening the part with a steam iron. It's worth to invest some printing to to get a clean finish like this (result of the really first try)

Example #1

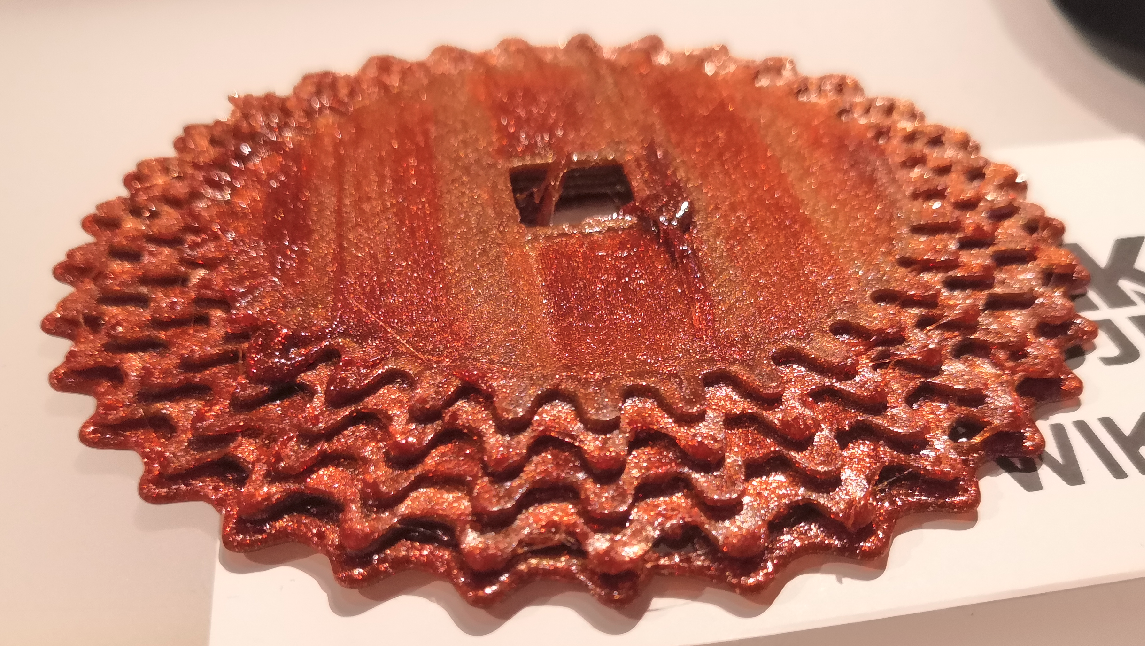

Example #2

Example 2 shows some "bugs" at the top layer. Too much material was extruded and heated up again.

Bridging / protruding outer contours

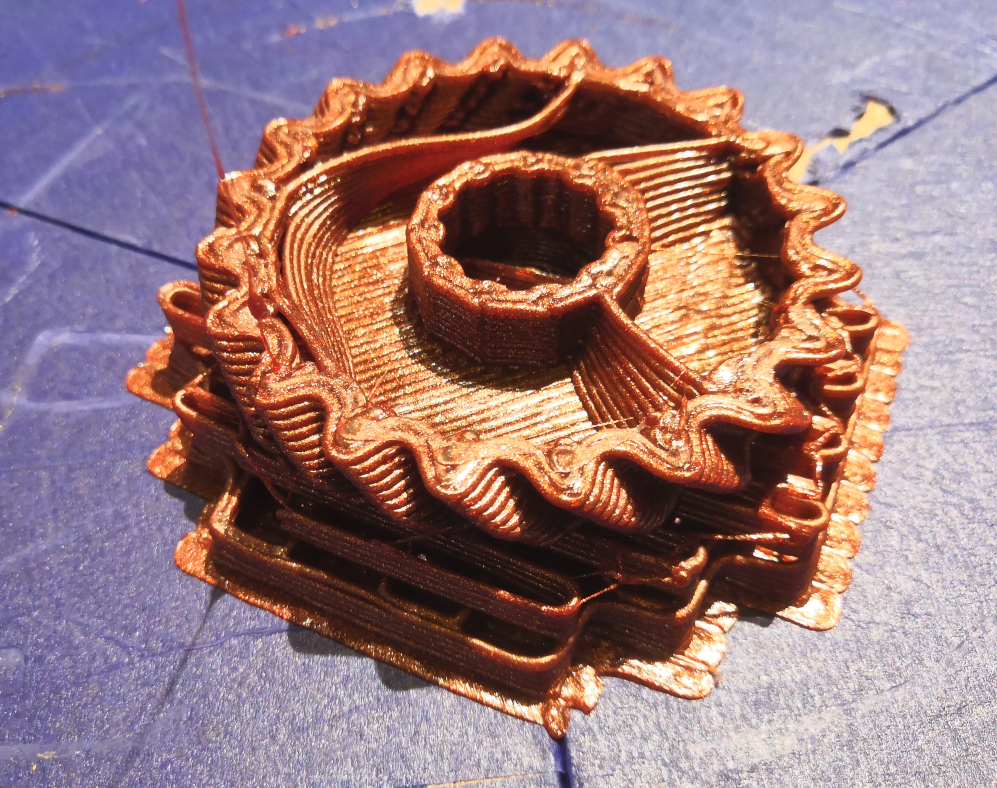

Support structures

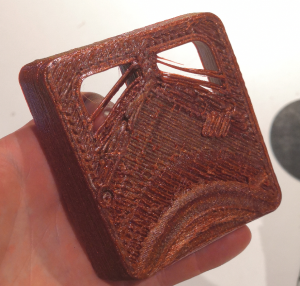

Also first try to work with support material. The bonding of PLA at the default painter's tape is good. But some ends do not stick really well. Have no good solution yet. The first layer height depends - it feels like +/- 0.2mm which is a large range to meet the requirements sticking thin walls like this. However, the print finished after second try (you can see the lower first layer height in relation to first try)

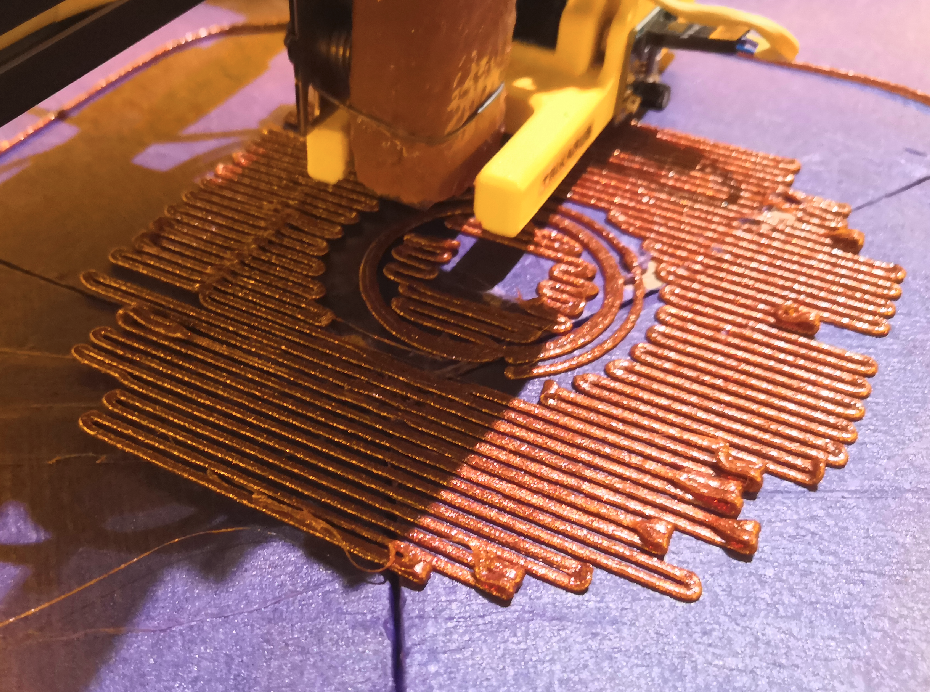

Extrusion widths and holes

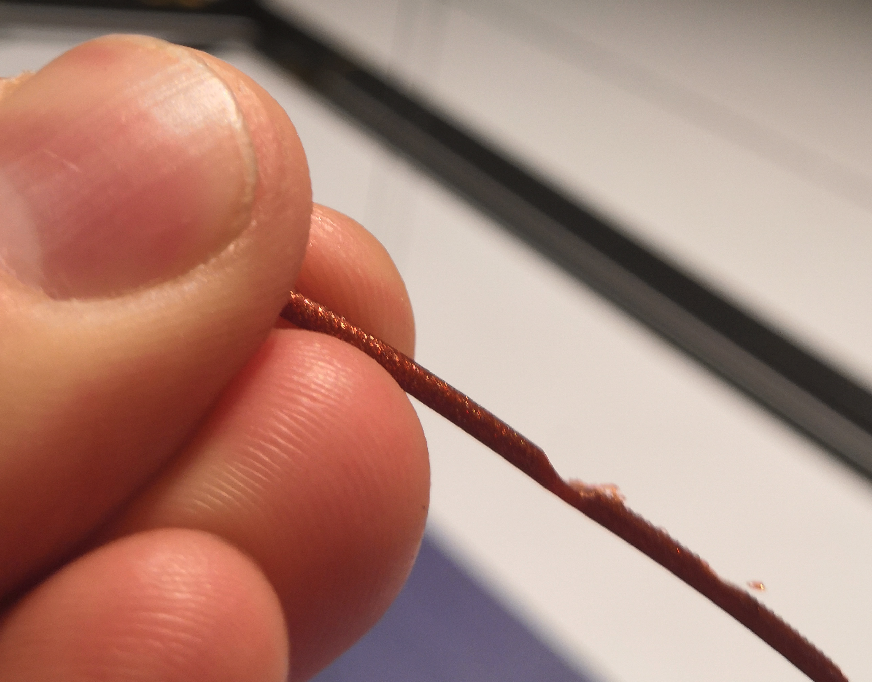

I got large over extrusions when printing. I did not recognize them last year because i just printed in spiral vase mode to evaluate print volume stuff. I needed to adjust the widths and enabled volumetric extrusion finally. The infill looks quite nice now (also raised the outer contour overlapping from 25% to 35%). Some holes are still getting created but this should be easy to fix soon.

More ToDos

After printing a lot of small stuff i got some more issues which need to be fixed to print without trouble in the mid of larger prints. I recognized stringing and grinding which are problematic.

To fix the stringing we might need to adjust the extrusion temperature from 215 °C to maybe 210°C or 205°C. But it will lower the maximum volumetric extrusion too. The maxium volumetric speed (MVS) needs to be corrected. At the moment i entered 110 mm³/s but this is far too much. Adjusting MVS should prevent filament string from grinding too i hope.

Comments1

Some edit from today

i reworked the page Longterm monitoring of Duet 2 and automatic Hotend PowerOff/Movement Stop because i added some monitoring and @pause action trigger (Repetier Server function) for Trikarus. This way we avoid dangerous moves when power loss occures randomly, or triggered by emergency stop button.